Showing posts with label Mechanics of Materials-1. Show all posts

Engineering Mechanics Lab

By : Asad Ali Arshad |

| Engineering Mechanics Lab |

Rack-Pinion animation.mp4

null

Worm Gear.mp4

null

Cam and Follower Mechanism in Engine - Magic Marks_2.mp4

null

Cam and Follower.pptx

null

Rack-Pinion animation.mp4

null

How Bevel Gears Work.mp4

null

Gear Train Mechanism.pptx

null

Mechanics of Material

By : Asad Ali Arshad |

| Mechanics of Material Chapter no 6 |

Mechanics of Material

6_shearing_stresses.pdf

null

Chapter no 6

Shearing Stress in Beams and Thin Walled Members

In this we will discussed the following topic and these topics are discussed in detail in the above given slides.

Introduction

Transverse loading applied to a beam

results in normal and shearing stresses in

transverse sections.

Distribution of normal and shearing

stresses satisfies.

When shearing stresses are exerted on the

vertical faces of an element, equal stresses

must be exerted on the horizontal faces.

Longitudinal shearing stresses must exist

in any member subjected to transverse

loading.

- Shear on a horizontal face of a beam

- Solved Example Problem 6.1

- Determination of Shearing Stress in a Beam

- Shearing Stress in Common Types of a Beam

- Solved Example Problem 6.2

- Shearing Stress in Thin Walled Members

Mechanics of Material

By : Asad Ali Arshad |

| Mechanics of Material Chapter no 5 |

Chapter no 5 : Mechanics of Material

Analysis and Designs of Beam for Bending

In the above slides we will discussed this chapter in detail and solved some of the conceptual questions.

We will cover the following topics of this chapter

A safe design requires that the maximum normal stress be

less than the allowable stress for the material used. This

criteria leads to the determination of the minimum

acceptable section modulus.

Among beam section choices which have an acceptable

section modulus, the one with the smallest weight per unit

length or cross sectional area will be the least expensive

and the best choice

We will cover the following topics of this chapter

Introduction to this chapter

Objective - Analysis and design of beams

• Transverse loadings of beams are classified as

concentrated loads or distributed loads

• Applied loads result in internal forces consisting

of a shear force (from the shear stress

distribution) and a bending couple (from the

normal stress distribution)

• Normal stress is often the critical design criteria

|

| Bending moment |

Requires determination of the location and

magnitude of largest bending moment.

Classification of Beams

Shear and Bending Moment Diagram

- Determination of maximum normal and shearing stress requires identification of maximum internal shear force and bending couple.

- Shear force and bending moment at a point determined by passing a section through the beam and applying an equilibrium analysis on the beam portions on either side of the section.

Solved Sample Problem 5.1

Solved Sample Problem 5.2

Relation between load shear and bending moment

Solved Sample Problem 5.3

Solved Sample Problem 5.4

Design of prismatic beams for bending

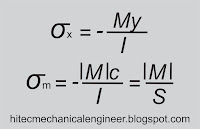

The largest normal stress is found at the surface where the

maximum bending moment occurs.

|

| Bending Moment |

less than the allowable stress for the material used. This

criteria leads to the determination of the minimum

acceptable section modulus.

|

| Section Modulus |

chap-5.pdf

null

Among beam section choices which have an acceptable

section modulus, the one with the smallest weight per unit

length or cross sectional area will be the least expensive

and the best choice

Solved Sample Problem 5.8

For more detail download the above slides..

Mechanics of Material

By : Asad Ali ArshadIn these slides following topic of the chapter no 2 are discussed in detail these are:

chap-2 (1).pdf

null

- Stress and Strain : Axial loading

- Normal Strain

- Stress Strain Curve

- Stress Strain Diagram: Ductile Material

- Stress Strain Diagram: Brittle Material

- Hooks Law Modulus of Elasticity

- Fatigue

- Deformation under Axial loading

- Generlized Hooks law

- Bulk Modulus

- Shearing Strain

- Relation among E, v and G

- Composite Material

- Saint-Venant's principle

- Stress Concentration Hole

- Stress Concentration fillet

- Elastoplastic Material

- Residual Stresses

- Poisson's Ratio

Mechanics of Material

By : Asad Ali ArshadThe content of this chapter are given below. All these topics are discussed in detail in the given slides and also alot of sample problems are solved for the convince of student.

Meet Google Drive - One place for all your files

Google Drive is a free way to keep your files backed up and easy to reach from any phone, tablet, or computer. Start with 15GB of Google storage - free.

- Concept of Stress

- Review of Statics

- Structure Free-Body Diagram

- Component Free-Body Diagram

- Method of Joints

- Stress Analysis

- Design

- Axial Loading: Normal Stress

- Centric & Eccentric Loading

- Shearing Stress

- Shearing Stress Examples

- Bearing Stress in Connections

- Stress Analysis & Design Example

- Rod & Boom Normal Stresses

- Pin Shearing Stresses

- Pin Bearing Stresses

- Stress in Two Force Members

- Stress on an Oblique Plane

- Maximum Stresses

- Stress Under General Loadings

- State of Stress

- Factor of Safety

Mechanics of Material

By : Asad Ali Arshadchap-4.pdf

null

In these slides we will discuss the chapter no 4 of mechanics of material which is related to the concepts of "Pure Bending". The aim of teaching this chapter are

Introduce students to bending behavior

Define the deformations, strains, and normal stresses in beams subject

to pure bending

Describe the behavior of composite beams made of more than one

material

Review stress concentrations and how they are included in the design

of beams

Study plastic deformations to determine how to evaluate beams made

of Elastoplast materials

Analyze members subject to eccentric axial loading, involving both

axial stresses and bending stresses

Review beams subject to unsymmetrical bending, i.e., where bending

does not occur in a plane of symmetry

Study bending of curved members

The content of this chapters are:

- Pure Bending

- Other Loading Types

- Symmetric Member in Pure Bending

- Bending Deformations

- Strain Due to Bending

- Beam Section Properties

- Properties of American Standard Shapes

- Deformations in a Transverse Cross Section

- Sample Problem 4.2

- Bending of Members Made of Several

- Materials

- Example 4.03

- Reinforced Concrete Beams

- Sample Problem 4.4

- Stress Concentrations

- Plastic Deformations

- Members Made of an Elastoplastic Material

- Example 4.03

- Reinforced Concrete Beams

- Sample Problem 4.4

- Stress Concentrations

- Plastic Deformations

- Members Made of an Elastoplastic Material

- Plastic Deformations of Members With a Single

- Plane of S...

- Residual Stresses

- Example 4.05, 4.06

- Eccentric Axial Loading in a Plane of Symmetry

- Example 4.07

- Sample Problem 4.8

- Unsymmetric Bending

- Example 4.08

- General Case of Eccentric Axial Loading

- 4 -

Mechanics of Material

By : Asad Ali Arshad

In these slides we will cover the following topics

chap-3.pdf

null

- Introduction

- Torsional Loads on Circular Shafts

- Net Torque Due to Internal Stresses

- Axial Shear Components

- Shaft Deformations

- Shearing Strain

- Stresses in Elastic Range

- Normal Stresses

- Torsional Failure Modes

- Sample Problem 3.1

- Angle of Twist in Elastic Range

- Statically Indeterminate Shafts

- Sample Problem 3.4

- Design of Transmission Shafts

- Stress Concentrations

- Plastic Deformations

- Elastoplastic Materials

- Residual Stresses

- Example 3.08/3.09

- Torsion of Noncircular Members

- Thin-Walled Hollow Shafts

- Introduce students to the concept of torsion in structural members and machine parts.

- Define shearing stresses and strains in a circular shaft subject to

- torsion

- Define angle of twist in terms of the applied torque, geometry of

- the shaft, and material

- Use torsional deformations to solve indeterminate problems

- Design shafts for power transmission

- Review stress concentrations and how they are included in torsion

- problems

- Describe the elastic-perfectly plastic response of circular shafts

- Analyze torsion for noncircular members

- Define the behavior of thin-walled hollow shafts

Mechanics of Material

By : Asad Ali Arshad

In these slides following topics are discussed in detail and some of the example problems related to these topics are also available.

The lecture 1 is actually Chapter 1 and Lecture 2 is Chapter 2 in both these to lecture we will basically complete two chapters of Mechanics of Material 7th Edition.

Chapter no 2 : Stress and Strain Axial Loading

The following topics are included in this chapter..

- Stress & Strain: Axial Loading

- Normal Strain

- Stress-Strain Test

- Stress-Strain Diagram: Ductile Materials

- Stress-Strain Diagram: Brittle Materials

- Hooke’s Law: Modulus of Elasticity

- Elastic vs. Plastic Behavior

- Fatigue

- Deformations Under Axial Loading

- Example 2.01

- Sample Problem 2.1

- Static Indeterminacy

- Example 2.04

- Thermal Stresses

- Poisson’s Ratio

- Generalized Hooke’s Law

- Dilatation: Bulk Modulus

- Shearing Strain

- Example 2.10

- Relation Among E, n, and G

- Sample Problem 2.5

- Composite Materials

- Saint-Venant’s Principle

- Stress Concentration: Hole

- Stress Concentration: Fillet

- Example 2.12

- Elastoplastic Materials

- Plastic Deformations

- Residual Stresses

- Example 2.14, 2.15, 2.16

2_axial_loading.pdf

null

Mechanics of Material

By : Asad Ali ArshadMechanics of Material Book 7th Edition is uploaded now you can get it through the following link.

Mechanics_of_Materials_7th_edition_beer..pdf

null

Hitec Mechanical Engineering

Mechanical Engineeirng Hitec Mechanical Engineering As we know Mechanical Engineering is the branch of engineering dealing with the des...