Showing posts with label fluid mechanics. Show all posts

Fluid Mechanics Lab

By : Asad Ali Arshad |

| Bourden Tube Experiment |

1. Dead Weight Calibrator.pptx

null

To Calibrate a Bourdon Type Pressure Gauge Using a Dead Weight Pressure Gauge Calibrator

Theoretical Background

1. Calibration: To check error with comparison to some standard device is called calibration.

2. Absolute Pressure (Pabs): The pressure that is taken with reference to absolute zero is called absolute pressure, and at absolute zero there is a perfect vacuum.

3. Gauge Pressure (Pg): The pressure that is taken with reference to atmospheric pressure is called gauge pressure. It may be positive or negative depending upon whether we take (Pg) above the atmospheric pressure or below the atmospheric pressure. Gauge pressure is always measured with atmospheric pressure, that is why when gauge pressure is at atmospheric pressure it results zero.

Pabs = Patm + Pgau

Bourdon Tube Pressure Gauge:

uThe bourdon tube pressure gauge is the most common type used to measure fluid pressure because it is reliable, inexpensive and relatively simple.

uThe bourdon tube is a curved tube closed at one end, which is attached to a spring-loaded mechanism that is itself attached to the gauge’s needle.

uThe port of the gauge is attached to the location in the system where you’re measuring pressure.

As pressure increases within the bourdon tube, the metal tube starts to straighten, and as it does, it tugs on the lever attached to the needle.

Apparatus: Dead Weight Tester

Procedure:

1. Remove the piston from unit.2. Close valve V1 and open valve V2.

3. Fill cylinder with oil.

4. Now close valve V2.

5. Put piston back in position with V1 and V2 in close position.

6. Read out pressure value on gauge and compare it with theoretical results.

7. Repeat the experiment by adding weights.

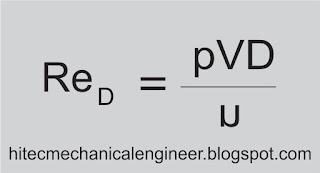

Reynolds Number

By : Asad Ali ArshadThe Reynolds number is undoubtedly the most famous dimensionless

parameter in fluid mechanics. It is named in honor of Osborne Reynolds (1842–1912), a

British engineer who first demonstrated that this combination of variables could be used as a criterion

to distinguish between laminar and turbulent flow. In most fluid flow problems there will

be a characteristic length, and a velocity, V, as well as the fluid properties of density, and

viscosity, which are relevant variables in the problem. Thus, with these variables the Reynolds

number

arises naturally from the dimensional analysis. The Reynolds number is a measure of the ratio of

the inertia force on an element of fluid to the viscous force on an element. When these two types

of forces are important in a given problem, the Reynolds number will play an important role. However,

if the Reynolds number is very small xthis is an indication that the viscous forces

are dominant in the problem, and it may be possible to neglect the inertial effects; that is, the density

of the fluid will not be an important variable. Flows at very small Reynolds numbers are commonly

referred to as “creeping flows”. Conversely, for large Reynolds

number flows, viscous effects are small relative to inertial effects and for these cases it may be

possible to neglect the effect of viscosity and consider the problem as one involving a “nonviscous”

fluid. This type of problem is considered in detail in Sections 6.4 through 6.7. An example

of the importance of the Reynolds number in determining the flow physics is shown in the figure

in the margin for flow past a circular cylinder at two different Re values

parameter in fluid mechanics. It is named in honor of Osborne Reynolds (1842–1912), a

British engineer who first demonstrated that this combination of variables could be used as a criterion

to distinguish between laminar and turbulent flow. In most fluid flow problems there will

be a characteristic length, and a velocity, V, as well as the fluid properties of density, and

viscosity, which are relevant variables in the problem. Thus, with these variables the Reynolds

number

|

| Reynolds Number |

arises naturally from the dimensional analysis. The Reynolds number is a measure of the ratio of

the inertia force on an element of fluid to the viscous force on an element. When these two types

of forces are important in a given problem, the Reynolds number will play an important role. However,

if the Reynolds number is very small xthis is an indication that the viscous forces

are dominant in the problem, and it may be possible to neglect the inertial effects; that is, the density

of the fluid will not be an important variable. Flows at very small Reynolds numbers are commonly

referred to as “creeping flows”. Conversely, for large Reynolds

number flows, viscous effects are small relative to inertial effects and for these cases it may be

possible to neglect the effect of viscosity and consider the problem as one involving a “nonviscous”

fluid. This type of problem is considered in detail in Sections 6.4 through 6.7. An example

of the importance of the Reynolds number in determining the flow physics is shown in the figure

in the margin for flow past a circular cylinder at two different Re values

Hitec Mechanical Engineering

Mechanical Engineeirng Hitec Mechanical Engineering As we know Mechanical Engineering is the branch of engineering dealing with the des...